- JTC Cubic Screw Jack

- JTM Worm Screw Jack

- JSS Stainless Steel Jack

- JT Acme Screw Jack

- JTW Machine Screw Jack

- Through Holes Screw Jack

- Custom Made Screw Jack

- JT Classic Miter Gearbox

-

- Order Code for Classic Miter Gearbox

- Classic Miter Gearbox description

- JT15 Miter Gearbox

- JT19 Miter Gearbox

- JT25 Miter Gearbox

- JT32 Miter Gearbox

- JT40 Miter Gearbox

- JT45 Miter Gearbox

- JT50 Miter Gearbox

- JT60 Miter Gearbox

- JT72 Miter Gearbox

- JT85 Miter Gearbox

- Flange Input Solid Output Shaft Gearbox

- JTP Cubic Miter Gearbox

-

- Order Code for Cubic Miter Gearbox

- Cubic Miter Gearbox description

- JTP65 Small Miter Gearbox

- JTP90 Miter Gearbox

- JTP110 Miter Gearbox

- JTP140 Miter Gearbox

- JTP170 Miter Gearbox

- JTP210 Miter Gearbox

- JTP240 Miter Gearbox

- JTP280 Miter Gearbox

- Solid Input and Output Shafts Gearbox

- Solid Input and Hollow Output Gearbox

- Flange Input and Solid Output Gearbox

- Flange Input and Hollow Output Gearbox

- JTA Alu. Miter Gearbox

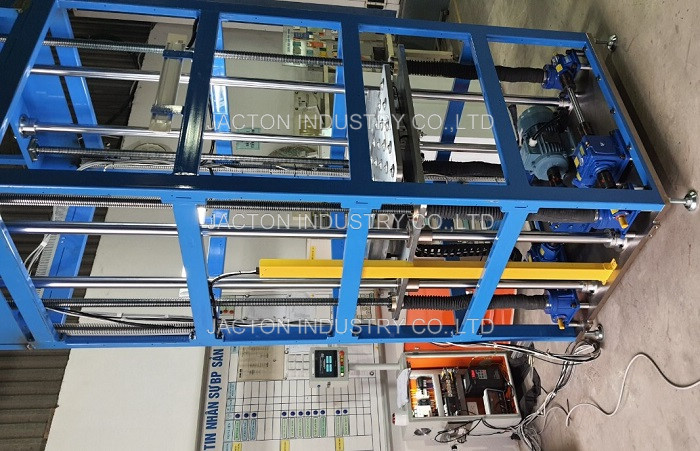

- Screw Jack System

- Lift System Accessories

-

- Flexible Jaw Coupling

- Overload Safety Couplings

- Aluminum Couplings

- Telescopic Universal Joint

- Rigid Shaft Couplings

- Universal Joint

- Cast Iron Hand Wheel

- Connecting Shafts

- Aluminum Handwheel

- YVF2 Series Variable Speed AC Motor

- Brake motors

- Three Phase Electric Motor

- Screw Jack Motor Flange

- Single Phase Induction Motors

- K Helical Bevel Geared Motor

- R Helical Geared Motor

- Worm Gear Reducer

- 12V 24V DC Geared Motor

- Proximity Switches

- Limit Switches

- Pillow Blocks

- Pillow Block Flange Bearing

- Digital Position Indicator

- Flange Blocks

- Ball Joint Rod End Bearing

- Bellows Boot

- Helical Gear Motor

- 12V 24V DC Motor

- Linear Bushings and Shafts

- Trunnion Adapters

- Servomotor

- Rotary Encoder

- Low Backlash Planetary Gearheads

- Stepper Motor

- 24V Planetary Gear Reducer

- Planetary Speed Reducer

- Frequency Inverter

- Hydraulic Cylinder Rod End Bearing

- Lift System Applications

- LAP Electric Linear Actuator

-

- 100KG Parallel Electromechanical Linear Actuators

- 250KG Parallel Electro Mechanical Linear Actuators

- 500KG Parallel Mount Rod Style Linear Actuators

- 630KG Parallel Mount Electric Cylinder Linear Actuators

- 1000KG Parallel Mount Industrial Linear Actuators Acme Screw

- 1600KG Parallel Electro-mechanical Actuators Heavy Duty

- 2500KG Parallel Mount Electric Cylinders Actuator

- 4000KG Heavy Duty Electric Linear Actuators Parallel Mount

- 6300KG Parallel Motor Drive Electric Actuator Linear Actuator

- 8000KG Parallel Electric Motor-Drive Linear Actuator

- 10000KG Parallel Mount Motorized Electric Linear Actuator

- 15000KG Parallel Industrial Motor Linear Actuator

- 20000KG Parallel Indistrial Motor Drive Linear Actuator

- 25000KG Parallel Electric Motor Linear Electric Actuator

- LA Electric Linear Actuators

-

- 10KG In-line Mini Electric Linear Actuators with Brake Motor

- 25KG In-line Electric Linear Actuator Push Rod

- 63KG In-line 700mm Stroke Electric Motor Linear Actuator

- 90KG In-line High Speed Motor Drive Electric Linear Actuator

- 100KG In-line Fast Speed Electric Linear Motor Linear Actuator

- 300KG Inline Industrial Electromechanical Linear Actuator

- 500KG In-Line Electric Linear Actuator

- 700KG Inline Heavy Electro Mechanical Actuators

- 1000KG In-line Heavy Duty AC Volt Industrial Linear Actuators

- JTE Classic Electric Cylinder

- Mechanical Linear Actuators

- JCA Cubic Electric Cylinder

Contact: Warren Lee

Contact: Warren Lee Skype: jactonjack

Skype: jactonjack T: 86-769-81585810

T: 86-769-81585810  F: 86-769-81585852

F: 86-769-81585852  E: sales@jactonindustry.com

E: sales@jactonindustry.com  W: www.screw-jack.com

W: www.screw-jack.com

* Main Products: Screw Jacks, Gearboxes, Linear Actuators.

* High Quality: 15+ Years of Export Quality Assurance. We have completed 100+ Large Projects, and 5000+ Customers are mainly located in 80+ Countries.

* Brand: JACTON. Factory Price. Most of the Standard Screw Jacks, Miter Gearboxes and Lift Systems are In Stock and Ready For Shipment.

* Vision & Mission: Provide a Complete Screw Jack Lifting System solutions. JACTON© high quality Screw Jacks and Bevel Gearboxes are used to replace the United States, Germany, United Kingdom, Italy, Austria, Switzerland, Japan and Taiwan international brand Screw Jacks and Gearboxes. Thereby reducing the production cost of customers.

* Other Advantages: Free 2D, 3D CAD Models. All Jacks and Gearboxes are with CE Certificate. Safety Transportation with strong standard export plywood cases materials (free fumigation). Quality Assured with double quality inspections. Original Inspection Reports, Operation Manual and Book Catalogue are put into the packages. Custom design available, OEM service available, Free engineering advice and Customer label available.

Dongguan JACTON Industry Co., Ltd, as a general taxpayer, VAT Number: 9144190007026567X3. Brand: JACTON. We are an audited professional manufacturer and supplier by SGS (Serial NO.: QIP-ASI192186), BV (Serial NO.: MIC-ASR202862), Domestic and International Alibaba, and Made in China organizations. All standard JACTON© Electric Screw Jack, Manual Screw Jack, Worm Screw Jack, Stainless Steel Jack, Ball Screw Jack, Bevel Gear Jack, Miter Gearbox, Lift System and Linear Actuators are with CE certifications. We have a strict quality system, with more than 10 senior engineers, more than 70 experienced skilled workers and practiced sales teams, and consistently provide the high quality linear drive systems to meet the customers electro-mechanical actuation, lifting and positioning needs. We guarantee quality, reliability, performance and value for today′s demanding industrial applications. Factory Sizes 7000-8000 square meters, processing with modern advanced machines such as CNC gear hobbing machines, CNC flank grinding machines, CNC cylindrical grinding machines, multi-axis CNC milling machines, CNC lathes, Machining centers and other equipment. Production Capacity: For Screw Jack, average annual production capacity 30000-40000 units, highestEver almost 50000 units, and average annual output value 30 million to 40 million CNY, approximately equal to 4.5 million to 6 million USD. For Bevel Gearboxes, average annual production capacity 20000-25000 units, highestEver almost 30000 units, and average annual output value 20 million to 25 million CNY, approximately equal to 3 million to 4 million USD. Inspection equipments include motor with inverter drive system, height adjustmemt motorized lifting system, coordinate measuring machines, outside micrometers, inside micrometers, depth calipers, vernier calipers, digital calipers, hardness testers, digital noise meters, industrial infrared thermometers, digital speed measuring instruments, digital multimeters, and high precision clamp digital ammeter etc.

Finished Projects in Countries

* Stage and Orchestra Platform Lifts Projects: China, France, Australia, Netherlands, United Kingdom, Spain and Canada.

* Hydroelectric Power Station Projects: China,Vietnam, Australia, Malaysia, Russia, Nepal, Pakistan, Belgium, United States and United Kingdom.

* Solar Tracker Projects: China, Spain, Canada.

* Aircraft Maintenance Platforms and Docking Systems Projects: China, Pakistan, Singapore and United Arab Emirates.

* Bolted Steel Storage Tanks & Silos Projects: China, South Africa, Egypt, United States, Mexico, Russia, Ethiopia, Brazil and Vietnam.

* Satellite Dish Antenna Project(Elevation and Azimuth Positioning): China, Singapore, Malaysia and United States.

* Rail Wagon Repair & Maintenance Project: China, South Africa.

* Beverage Can Production Lines: China, Netherlands, United States, Thailand and Indonesia.

* Steel Pipe Production Line: China, Iran, United States and Turkey.

Customers in Countries

* Asia: China, Malaysia, Indonesia, Singapore, Pakistan, Philippines, Vietnam, United Arab Emirates, Thailand, Saudi Arabia, Iran, Turkey, India, Nepal, Yemen, Taiwan, Sri Lanka, Israel, Jordan, Kuwait, Qatar.

* America: United States, Mexico, Canada, Chile, Bolivia, Brazil, Colombia, Dominican Republic, Honduras, Costa Rica, Panama, Puerto Rico, Jamaica, Trinidad and Tobago, Aruba, Argentina, Peru, Venezuela.

* Europe: Russia, Germany, Turkey, France, United Kingdom, Italy, Spain, Ukraine, Poland, Romania, Netherlands, Belgium, Greece, Czech Republic, Portugal, Sweden, Hungary, Belarus, Austria, Switzerland, Bulgaria, Denmark, Finland, Slovakia, Norway, Ireland, Croatia, Georgia, Armenia, Lithuania, Slovenia, Estonia, Cyprus, Luxembourg, Iceland.

* Australia: Australia, New Zealand.

* Africa: South Africa, Egypt, Ethiopia, Nigeria.

China Screw Jack,Ball Screw Jack,Machine Screw Jack,Worm Gear Screw Jack,Bevel Gear Screw Jack,Miter Gearbox,Screw Jack Lift System Manufacturer

.jpg)

.jpg)

.jpg)