Home» JCA Cubic Electric Cylinder » Product Detail

Products

THE NAME:

Electric Cylinder Actuator description

Model: JCA25-200, JCB25-200

Categories: JCA Cubic Electric Cylinder »

Place of Origin: Made In China

Brand Name: JACTON

Description:

Electric Cylinder Actuator Description

Electric Cylinder Actuator is for high load linear motion solutions with compact cubic gearbox design. Combined the advantages of Linear actuator and Screw Jack to achieve the high load lifting in industry application.The sealed and high protection class allow the actuator work even in harsh environments. Which is a good solution for Hydraulic and Pneumatic replacement to reduce cost and pollution.

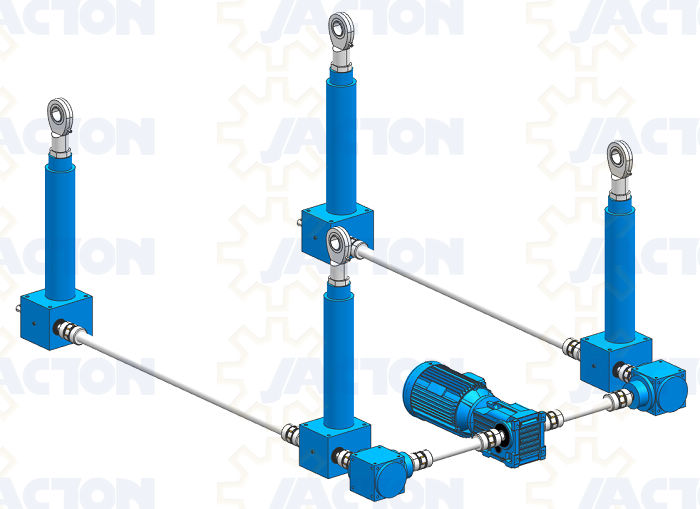

Synchronized Lifting, 2-18 pieces Electric Cylinder Actuators could be driven by one motor. Simple operation but reliable. Please contact our engineering for synchronized lifting system design. Electric cylinder actuators systems are widely application in tunnel freezers, frying machine, polysilicon ingot furnace, monocrystalline silicon in the photovoltaic industry, vehicle lifters in the vehicle manufacturing industry, flexible tooling and welding lifts, medical devices, woodworking machinery, food machinery, aerospace, defense military, and astronomical telescopes remote control actuators.

Alternative JCB Ball Screw Electric Cylinder Actuator and JCA Acme Screw Electric Cylinder Actuator. Load capacity from 2 ton to 20 ton, could be classified as 2 ton, 5 ton , 8 ton , 10 ton , 20 ton unit. Max. speed and stroke could reach 100mm/s and 2.5m. Duty cycle 50%. In the absence of vibration load, JCA acme screw electric cylinder actuator has self-locking and precisely position loads, will hold loads without backdriving. NOTE: Brake motors must be specified for all JCB ball screw electric cylinder actuators. And for any acme screw electric cylinder actuator with an efficiency ratio greater than or equal to 30%.

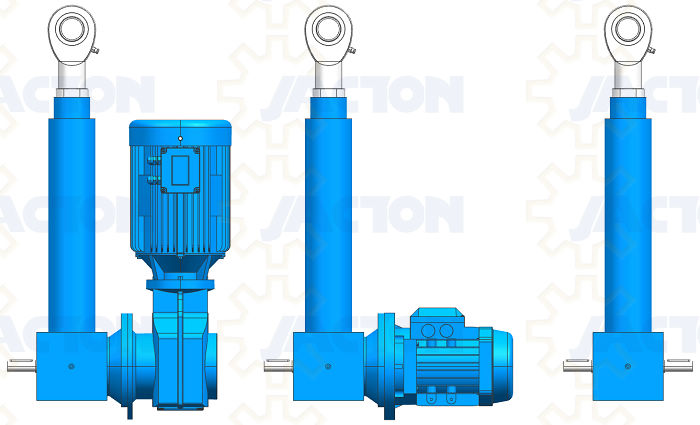

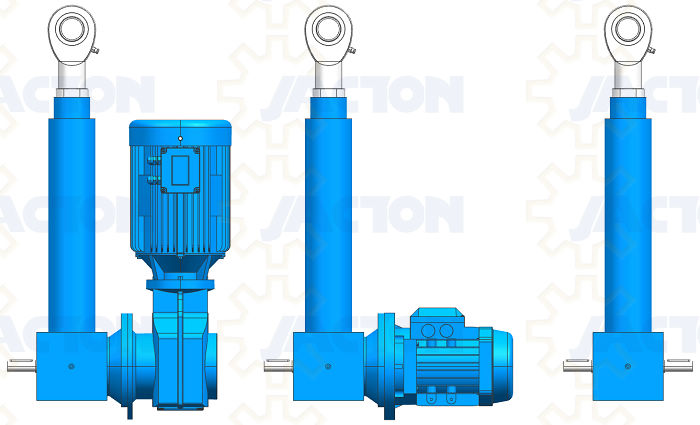

The Electric Cylinder Actuator can be ordered to accept the motor type of your choice, whether geared motor,or AC motor etc. The electric cylinder actuator offers flexibility in order to accept any type to meet your requirement. Available in Standard mount (double input shafts), Direct Motor Mounts and Parallel Motor Mounts with additional gear reducer.

Electric Cylinder Actuator Material

* Acme Screw: S45C. Custom stainless steel.

* Translating Tube(Push Rod): High strength steel. Custom stainless steel.

* External Protection Tube: High strength steel. Custom stainless steel.

* Worm(Input Shaft): Hardened worm, S45C. Custom stainless steel.

* Worm Gear(Wheel): High strength bronze.

* Travelling Nut: High strength bronze.

* Housing: Ductile Iron. Custom stainless steel.

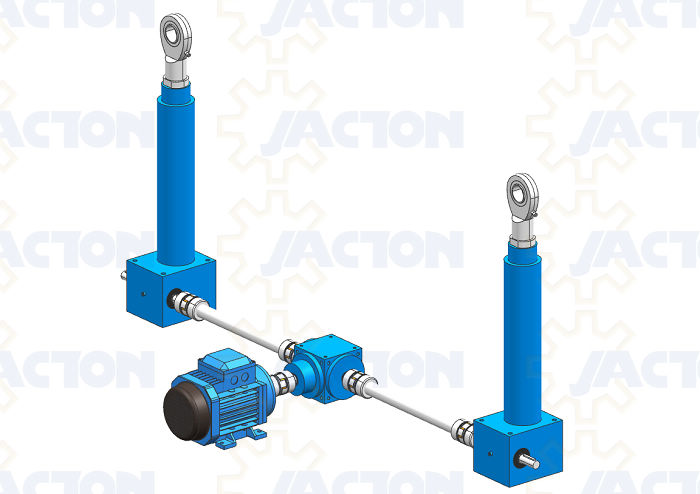

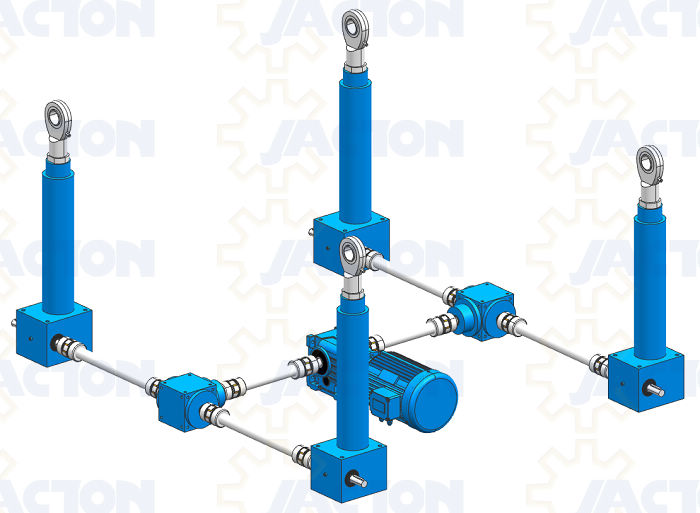

Applications of Synchronized Lifting

Jacton Industry provided complete lifting system design and components, Which including electric cylinder actuators, motors, bevel gearboxes, connecting shafts, couplings, brake, clutch etc. Customer just need let us know your requirement of total load capacity, speed, stroke and dimension, Our engineering will provided you a design scheme with calculation process and components selection, CAD drawing is also available.

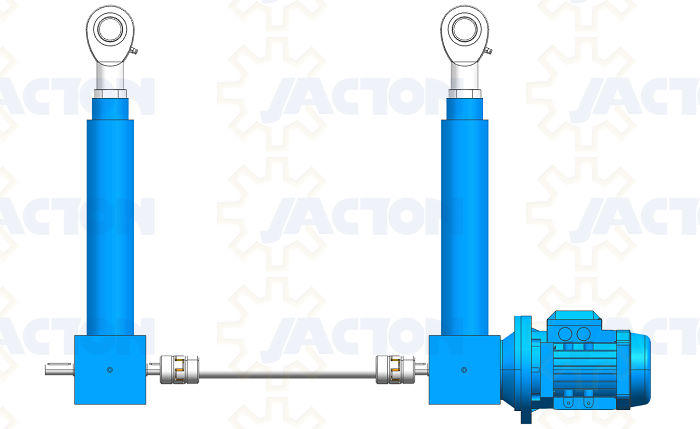

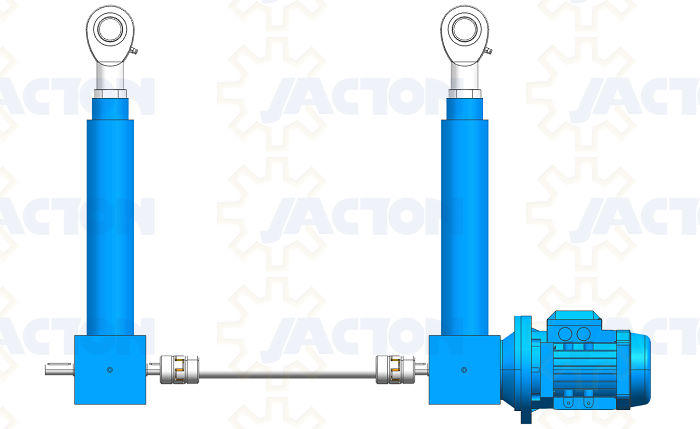

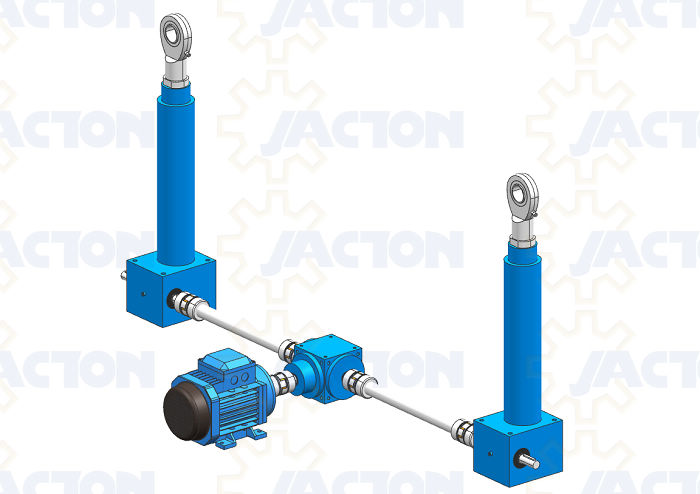

Synchronized Lifting System of Two Electric Cylinder Actuators (I- and T-configuration)

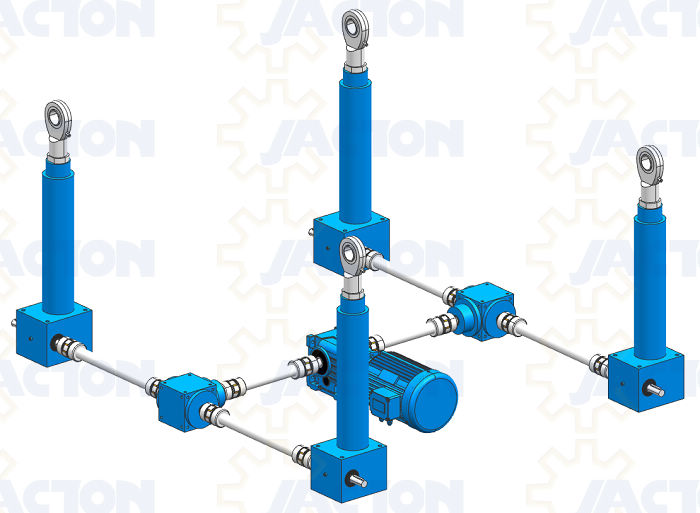

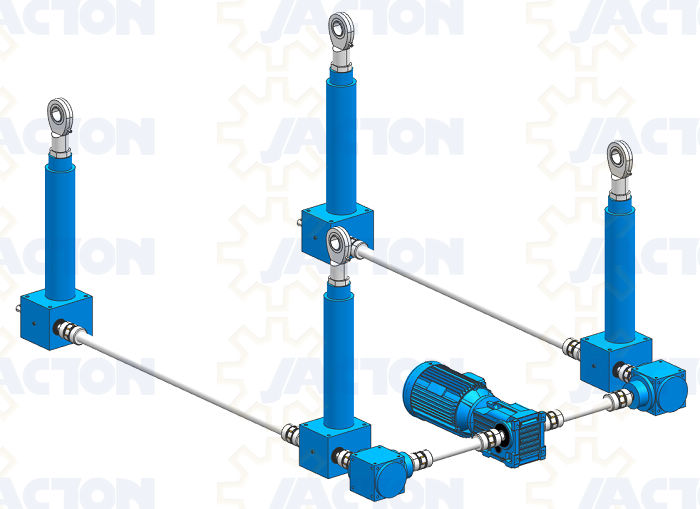

Synchronized Lifting System of Four Electric Cylinder Actuators (H- and U-configuration)

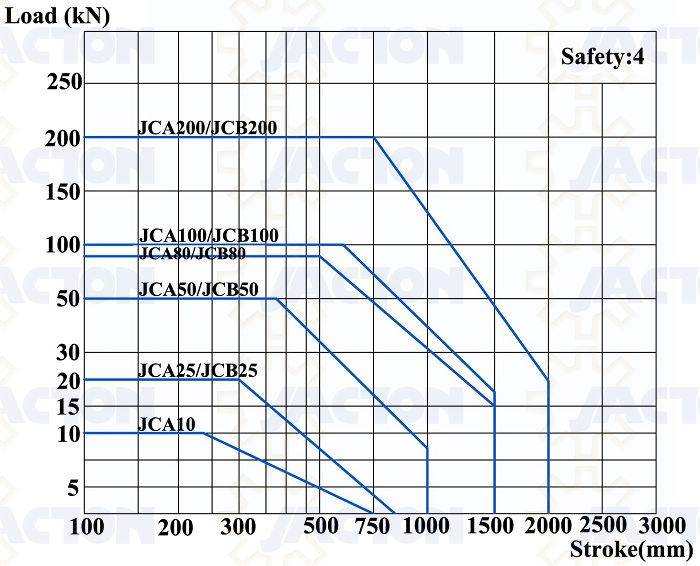

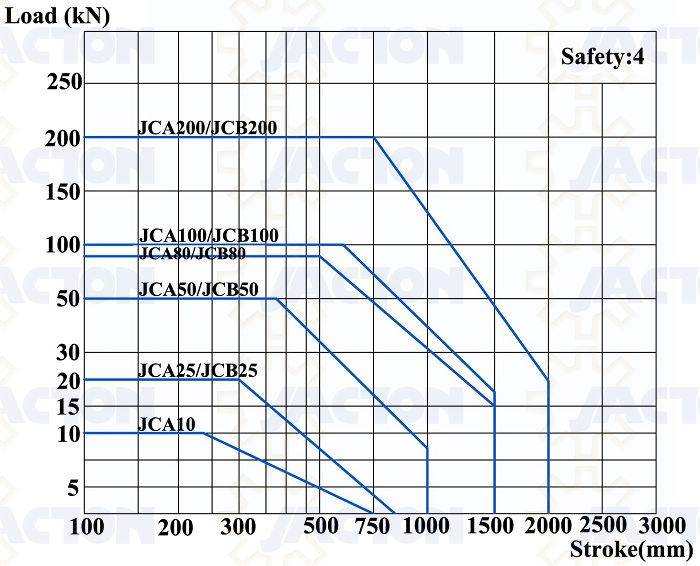

Permissible Critical Bucking Force of Electric Cylinder Actuator

The primary electric cylinder actuators size selection factor is the bucking resistance of screw shaft, Also know as Euler cures, the graphs (Euler 2: Guided) below give safety operating state for each size of electric cylinder. Buckling limits are relevant for compressive load only.

Electric Cylinder Actuator Accessories

Synchronized Lifting, 2-18 pieces Electric Cylinder Actuators could be driven by one motor. Simple operation but reliable. Please contact our engineering for synchronized lifting system design. Electric cylinder actuators systems are widely application in tunnel freezers, frying machine, polysilicon ingot furnace, monocrystalline silicon in the photovoltaic industry, vehicle lifters in the vehicle manufacturing industry, flexible tooling and welding lifts, medical devices, woodworking machinery, food machinery, aerospace, defense military, and astronomical telescopes remote control actuators.

Alternative JCB Ball Screw Electric Cylinder Actuator and JCA Acme Screw Electric Cylinder Actuator. Load capacity from 2 ton to 20 ton, could be classified as 2 ton, 5 ton , 8 ton , 10 ton , 20 ton unit. Max. speed and stroke could reach 100mm/s and 2.5m. Duty cycle 50%. In the absence of vibration load, JCA acme screw electric cylinder actuator has self-locking and precisely position loads, will hold loads without backdriving. NOTE: Brake motors must be specified for all JCB ball screw electric cylinder actuators. And for any acme screw electric cylinder actuator with an efficiency ratio greater than or equal to 30%.

The Electric Cylinder Actuator can be ordered to accept the motor type of your choice, whether geared motor,or AC motor etc. The electric cylinder actuator offers flexibility in order to accept any type to meet your requirement. Available in Standard mount (double input shafts), Direct Motor Mounts and Parallel Motor Mounts with additional gear reducer.

Electric Cylinder Actuator Material

* Acme Screw: S45C. Custom stainless steel.

* Translating Tube(Push Rod): High strength steel. Custom stainless steel.

* External Protection Tube: High strength steel. Custom stainless steel.

* Worm(Input Shaft): Hardened worm, S45C. Custom stainless steel.

* Worm Gear(Wheel): High strength bronze.

* Travelling Nut: High strength bronze.

* Housing: Ductile Iron. Custom stainless steel.

Applications of Synchronized Lifting

Jacton Industry provided complete lifting system design and components, Which including electric cylinder actuators, motors, bevel gearboxes, connecting shafts, couplings, brake, clutch etc. Customer just need let us know your requirement of total load capacity, speed, stroke and dimension, Our engineering will provided you a design scheme with calculation process and components selection, CAD drawing is also available.

Synchronized Lifting System of Two Electric Cylinder Actuators (I- and T-configuration)

Synchronized Lifting System of Four Electric Cylinder Actuators (H- and U-configuration)

Permissible Critical Bucking Force of Electric Cylinder Actuator

The primary electric cylinder actuators size selection factor is the bucking resistance of screw shaft, Also know as Euler cures, the graphs (Euler 2: Guided) below give safety operating state for each size of electric cylinder. Buckling limits are relevant for compressive load only.

Electric Cylinder Actuator Accessories

* Motorized driven (AC or DC) by asynchronous motors (normal, YEJ brake, YVP variable frequency, B explosion proof, D multi-speed), stepper motors, servo motors with encoders and controllers. IEC motor flange or NEMA C-Face motor adapter for connect with motors. Frequency inverters.

* Manually operation by Aluminum handwheels, or Cast iron handwheels.

* Connection Devices: Couplings. Universal joints. Telescopic universal joints. Connecting shafts.

* Screw Protective Devices: Bellows boot. Telescopic spring covers. Rigid Protective tubes.

* Safety Devices: Limit switches. Proximity switches. Safety nuts. Anti-backlash nut. Overload safety couplings. Stop nuts. Position Encoders. Overload clutch. Brake motor. Linear braking elements. Wear detection/monitors. Linear guides and rails. Potentiometer. Pressure sensor.

* Others Accessories: Travel nuts. Position indicators. Trunnion adapter plates. Trunnion mounting brackets. Pillow blocks. Flange blocks. Rod end bearings.

Previous Product:Order Code for Electric Cylinder Actuator

Next Product:none

Related Product

More products

Product List

Manual Electric Screw Jack

Worm Screw Jack

- JTC Cubic Screw Jack

- JTM Worm Screw Jack

- JSS Stainless Steel Jack

- JT Acme Screw Jack

- JTW Machine Screw Jack

- Through Holes Screw Jack

- Custom Made Screw Jack

Ball Screw Jack

Bevel Gear Jack

Miter Gearbox

- JT Classic Miter Gearbox

-

- Order Code for Classic Miter Gearbox

- Classic Miter Gearbox description

- JT15 Miter Gearbox

- JT19 Miter Gearbox

- JT25 Miter Gearbox

- JT32 Miter Gearbox

- JT40 Miter Gearbox

- JT45 Miter Gearbox

- JT50 Miter Gearbox

- JT60 Miter Gearbox

- JT72 Miter Gearbox

- JT85 Miter Gearbox

- Flange Input Solid Output Shaft Gearbox

- JTP Cubic Miter Gearbox

-

- Order Code for Cubic Miter Gearbox

- Cubic Miter Gearbox description

- JTP65 Small Miter Gearbox

- JTP90 Miter Gearbox

- JTP110 Miter Gearbox

- JTP140 Miter Gearbox

- JTP170 Miter Gearbox

- JTP210 Miter Gearbox

- JTP240 Miter Gearbox

- JTP280 Miter Gearbox

- Solid Input and Output Shafts Gearbox

- Solid Input and Hollow Output Gearbox

- Flange Input and Solid Output Gearbox

- Flange Input and Hollow Output Gearbox

- JTA Alu. Miter Gearbox

Lift System and Accessories

- Screw Jack System

- Lift System Accessories

-

- Flexible Jaw Coupling

- Overload Safety Couplings

- Aluminum Couplings

- Telescopic Universal Joint

- Rigid Shaft Couplings

- Universal Joint

- Cast Iron Hand Wheel

- Connecting Shafts

- Aluminum Handwheel

- YVF2 Series Variable Speed AC Motor

- Brake motors

- Three Phase Electric Motor

- Screw Jack Motor Flange

- Single Phase Induction Motors

- K Helical Bevel Geared Motor

- R Helical Geared Motor

- Worm Gear Reducer

- 12V 24V DC Geared Motor

- Proximity Switches

- Limit Switches

- Pillow Blocks

- Pillow Block Flange Bearing

- Digital Position Indicator

- Flange Blocks

- Ball Joint Rod End Bearing

- Bellows Boot

- Helical Gear Motor

- 12V 24V DC Motor

- Linear Bushings and Shafts

- Trunnion Adapters

- Servomotor

- Rotary Encoder

- Low Backlash Planetary Gearheads

- Stepper Motor

- 24V Planetary Gear Reducer

- Planetary Speed Reducer

- Frequency Inverter

- Hydraulic Cylinder Rod End Bearing

- Lift System Applications

Linear Actuators

- LAP Electric Linear Actuator

-

- 100KG Parallel Electromechanical Linear Actuators

- 250KG Parallel Electro Mechanical Linear Actuators

- 500KG Parallel Mount Rod Style Linear Actuators

- 630KG Parallel Mount Electric Cylinder Linear Actuators

- 1000KG Parallel Mount Industrial Linear Actuators Acme Screw

- 1600KG Parallel Electro-mechanical Actuators Heavy Duty

- 2500KG Parallel Mount Electric Cylinders Actuator

- 4000KG Heavy Duty Electric Linear Actuators Parallel Mount

- 6300KG Parallel Motor Drive Electric Actuator Linear Actuator

- 8000KG Parallel Electric Motor-Drive Linear Actuator

- 10000KG Parallel Mount Motorized Electric Linear Actuator

- 15000KG Parallel Industrial Motor Linear Actuator

- 20000KG Parallel Indistrial Motor Drive Linear Actuator

- 25000KG Parallel Electric Motor Linear Electric Actuator

- LA Electric Linear Actuators

-

- 10KG In-line Mini Electric Linear Actuators with Brake Motor

- 25KG In-line Electric Linear Actuator Push Rod

- 63KG In-line 700mm Stroke Electric Motor Linear Actuator

- 90KG In-line High Speed Motor Drive Electric Linear Actuator

- 100KG In-line Fast Speed Electric Linear Motor Linear Actuator

- 300KG Inline Industrial Electromechanical Linear Actuator

- 500KG In-Line Electric Linear Actuator

- 700KG Inline Heavy Electro Mechanical Actuators

- 1000KG In-line Heavy Duty AC Volt Industrial Linear Actuators

- JTE Classic Electric Cylinder

- Mechanical Linear Actuators

- JCA Cubic Electric Cylinder

Application

Jacton Industry Co.,Ltd.

Contact: Warren Lee

Contact: Warren Lee

Skype: jactonjack

Skype: jactonjack

T: 86-769-81585810

T: 86-769-81585810

F: 86-769-81585852

F: 86-769-81585852

E: sales@jactonindustry.com

E: sales@jactonindustry.com

W: www.screw-jack.com

W: www.screw-jack.com

Contact: Warren Lee

Contact: Warren Lee Skype: jactonjack

Skype: jactonjack T: 86-769-81585810

T: 86-769-81585810  F: 86-769-81585852

F: 86-769-81585852  E: sales@jactonindustry.com

E: sales@jactonindustry.com  W: www.screw-jack.com

W: www.screw-jack.com

VAT No. 9144190007026567X3, Copyright ©2013 www.screw-jack.com Jacton Industry Co.,Ltd. All Rights Reserved Site Map

Building 2, No. 1, DongCheng Road, Chang An, Dongguan, Guangdong, China. Phone: 86-769-81585810 | Fax: 86-769-81585852

China Screw Jack,Ball Screw Jack,Machine Screw Jack,Worm Gear Screw Jack,Bevel Gear Screw Jack,Miter Gearbox,Screw Jack Lift System Manufacturer

China Screw Jack,Ball Screw Jack,Machine Screw Jack,Worm Gear Screw Jack,Bevel Gear Screw Jack,Miter Gearbox,Screw Jack Lift System Manufacturer