Home» LA Electric Linear Actuators » Product Detail

Products

THE NAME:

700KG Inline Heavy Electro Mechanical Actuators

Model: LA700

Categories: LA Electric Linear Actuators »

Place of Origin: Made In China

Brand Name: JACTON

Description:

Electromechanical Linear Actuator Designs: Most electromechanical designs incorporate a lead screw and lead nut, while some use a ball screw and ball nut. In either case, the screw may be connected to a motor or manual control knob either directly or through a series of gears. Gears are typically used to allow a smaller, weaker motor, rotating at a higher RPM to be geared down to provide the torque necessary to rotate the screw under a heavier load than the motor would otherwise be capable of driving directly. Generally speaking, this approach effectively sacrifices linear actuator speed in favor of increased actuator thrust. In some applications the use of a worm gear is common, as this approach allows a smaller built-in dimension, while allowing for greater travel length.

A traveling-nut linear actuator has a motor that stays attached to one end of the lead screw (perhaps indirectly through a gearbox). The motor rotates the lead screw, and the lead nut is restrained from rotating, therefore the nut "travels" up and down the lead screw.

A traveling-screw linear actuator has a lead screw that passes entirely through the motor. In a traveling-screw linear actuator, the motor "crawls" up and down a lead screw that is restrained from rotating. The only rotating parts are inside the motor. In some designs, the rotating parts may not even be visible from the outside of the linear actuator.

Some lead screws have multiple "starts". This means that they have multiple threads alternating on the same shaft. One simple way to visualize the multiple starts lead screw is the multiple color stripes on a candy cane. Multiple starts lead screws provide for more adjustment capability between thread pitch and the nut/screw thread contact area, which will determine the extension speed and load carrying capacity (of the threads), respectively.

Linear actuators are used in industrial automation and machinery, machine tools, computer peripherals such as disk drives and printers, home automation, packaging, assembly, electronic manufacturing, data storage, laser processing, and test and inspection. Linear actuators are typically used in applications along with motors, valves, pumps, switches, dampers, and in many other places where linear motion is required. Linear actuators are also used for medical imaging and diagnostics, solar, farming, construction, automotive, and robotics applications.

Linear actuators are used in nearly every type of electrical device that requires linear motion. Power drills, pumps, and other industrial appliances often rely on linear actuators to move other objects. Linear actuators are also used in some types of motors, and are often used in the robotics industry to provide robots with motor skills. In fact, a simple piston inside of an electric motor or fuel-injection engine uses linear motion, and therefore acts as a linear actuator.

700KG Inline Heavy Electro Mechanical Actuators, 700kgf 1000mm 40 Inch Stroke Motorized Electric Actuator to Replace Pneumatic Linear Actuator with a Piston Inside a Cylinder. 700KG Inline Heavy Electro Mechanical Actuators features include heavy load capacity, high linear speed, long service life, low noise system, no oil leaks, contamination or fire risk, accurate and repeatable positioning using simplified system, easy synchronization, easy installation, no pipework, powerpack and valves, choice of end fittings like clevis, threaded end, top plate, trunnion mounting (with or without feet), proximity switches, guided ram (guiding the load side loads on the actuator ram should be avoided by ensuring that the load is guided), and bellows boots. 700KG Inline Heavy Electro Mechanical Actuators can not only match the load capacity of hydraulic cylinders and exceed the load capacity of conventional electric linear actuators. Main application in coiling machines, decoiling machines, continuous operation process lines, tundish cars, scissor lifts, lifting platforms, robotics, continuous paint pumps, medical beds, gates, dampers, oven and processing tank doors, antennas, and agricultural equipment.

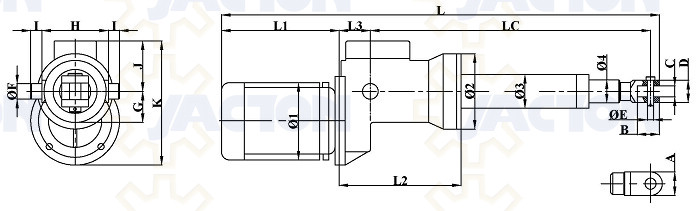

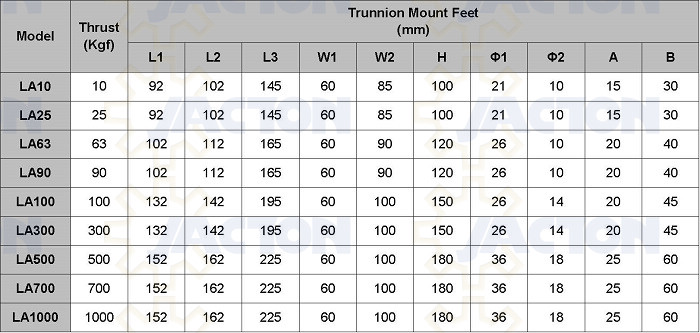

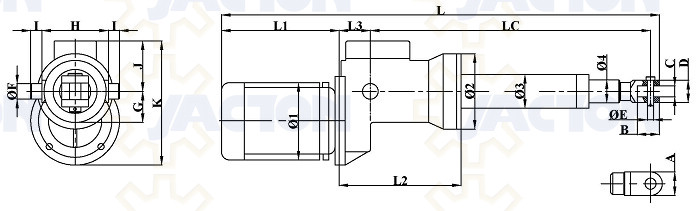

700KG Inline Heavy Electro Mechanical Actuators Technical Details & Drawings

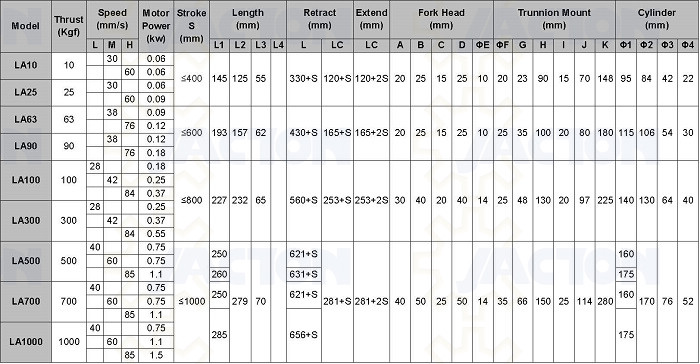

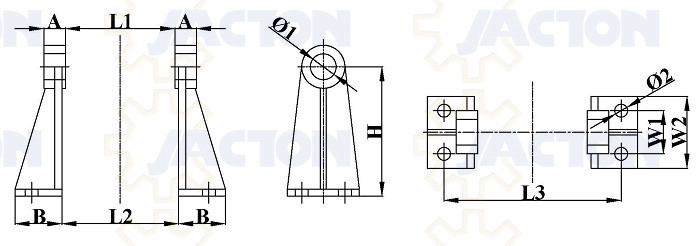

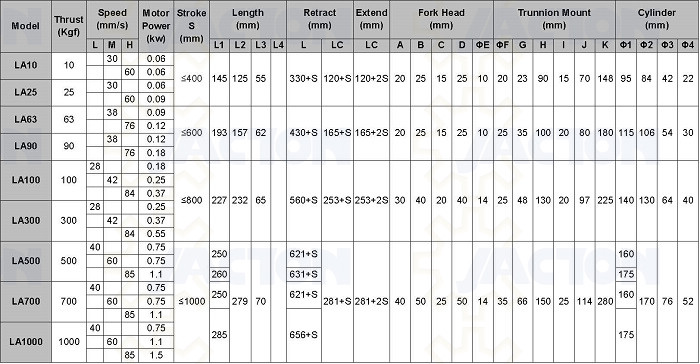

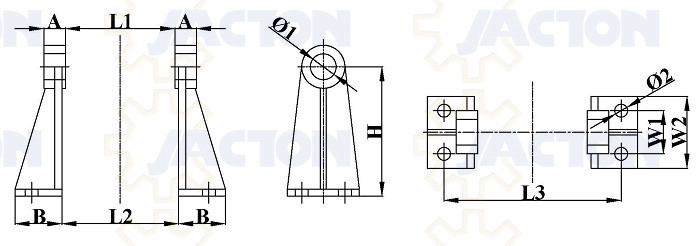

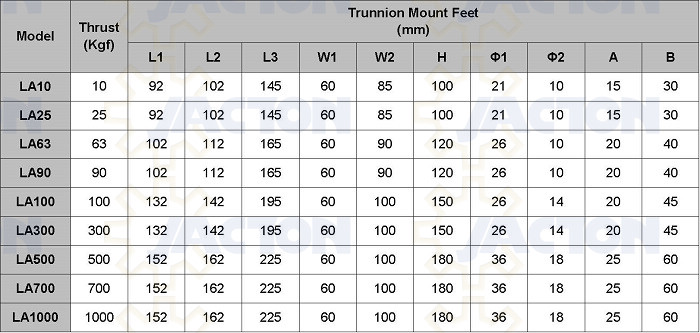

Trunnion Mounting Feet Drawings

700KG Inline Heavy Electro Mechanical Actuators are application in gates, dampers, oven and processing tank doors, antennas, orthopedic tables and other medical equipment, ergonomic furniture, and agricultural equipment, scissor lifts, scissor platforms, lifting platforms, robotics, continuous paint pumps, medical beds, coiling machines, tundish cars, continuous operation process lines opening and closing, tilting and pivoting, lifting and lowering, and positioning etc. Custom designs linear cylinders are also available for your special applications.

A traveling-nut linear actuator has a motor that stays attached to one end of the lead screw (perhaps indirectly through a gearbox). The motor rotates the lead screw, and the lead nut is restrained from rotating, therefore the nut "travels" up and down the lead screw.

A traveling-screw linear actuator has a lead screw that passes entirely through the motor. In a traveling-screw linear actuator, the motor "crawls" up and down a lead screw that is restrained from rotating. The only rotating parts are inside the motor. In some designs, the rotating parts may not even be visible from the outside of the linear actuator.

Some lead screws have multiple "starts". This means that they have multiple threads alternating on the same shaft. One simple way to visualize the multiple starts lead screw is the multiple color stripes on a candy cane. Multiple starts lead screws provide for more adjustment capability between thread pitch and the nut/screw thread contact area, which will determine the extension speed and load carrying capacity (of the threads), respectively.

Linear actuators are used in industrial automation and machinery, machine tools, computer peripherals such as disk drives and printers, home automation, packaging, assembly, electronic manufacturing, data storage, laser processing, and test and inspection. Linear actuators are typically used in applications along with motors, valves, pumps, switches, dampers, and in many other places where linear motion is required. Linear actuators are also used for medical imaging and diagnostics, solar, farming, construction, automotive, and robotics applications.

Linear actuators are used in nearly every type of electrical device that requires linear motion. Power drills, pumps, and other industrial appliances often rely on linear actuators to move other objects. Linear actuators are also used in some types of motors, and are often used in the robotics industry to provide robots with motor skills. In fact, a simple piston inside of an electric motor or fuel-injection engine uses linear motion, and therefore acts as a linear actuator.

700KG Inline Heavy Electro Mechanical Actuators, 700kgf 1000mm 40 Inch Stroke Motorized Electric Actuator to Replace Pneumatic Linear Actuator with a Piston Inside a Cylinder. 700KG Inline Heavy Electro Mechanical Actuators features include heavy load capacity, high linear speed, long service life, low noise system, no oil leaks, contamination or fire risk, accurate and repeatable positioning using simplified system, easy synchronization, easy installation, no pipework, powerpack and valves, choice of end fittings like clevis, threaded end, top plate, trunnion mounting (with or without feet), proximity switches, guided ram (guiding the load side loads on the actuator ram should be avoided by ensuring that the load is guided), and bellows boots. 700KG Inline Heavy Electro Mechanical Actuators can not only match the load capacity of hydraulic cylinders and exceed the load capacity of conventional electric linear actuators. Main application in coiling machines, decoiling machines, continuous operation process lines, tundish cars, scissor lifts, lifting platforms, robotics, continuous paint pumps, medical beds, gates, dampers, oven and processing tank doors, antennas, and agricultural equipment.

700KG Inline Heavy Electro Mechanical Actuators Technical Details & Drawings

Trunnion Mounting Feet Drawings

700KG Inline Heavy Electro Mechanical Actuators are application in gates, dampers, oven and processing tank doors, antennas, orthopedic tables and other medical equipment, ergonomic furniture, and agricultural equipment, scissor lifts, scissor platforms, lifting platforms, robotics, continuous paint pumps, medical beds, coiling machines, tundish cars, continuous operation process lines opening and closing, tilting and pivoting, lifting and lowering, and positioning etc. Custom designs linear cylinders are also available for your special applications.

Previous Product:500KG In-Line Electric Linear Actuator

Related Product

More products

Product List

Manual Electric Screw Jack

Worm Screw Jack

- JTC Cubic Screw Jack

- JTM Worm Screw Jack

- JSS Stainless Steel Jack

- JT Acme Screw Jack

- JTW Machine Screw Jack

- Through Holes Screw Jack

- Custom Made Screw Jack

Ball Screw Jack

Bevel Gear Jack

Miter Gearbox

- JT Classic Miter Gearbox

-

- Order Code for Classic Miter Gearbox

- Classic Miter Gearbox description

- JT15 Miter Gearbox

- JT19 Miter Gearbox

- JT25 Miter Gearbox

- JT32 Miter Gearbox

- JT40 Miter Gearbox

- JT45 Miter Gearbox

- JT50 Miter Gearbox

- JT60 Miter Gearbox

- JT72 Miter Gearbox

- JT85 Miter Gearbox

- Flange Input Solid Output Shaft Gearbox

- JTP Cubic Miter Gearbox

-

- Order Code for Cubic Miter Gearbox

- Cubic Miter Gearbox description

- JTP65 Small Miter Gearbox

- JTP90 Miter Gearbox

- JTP110 Miter Gearbox

- JTP140 Miter Gearbox

- JTP170 Miter Gearbox

- JTP210 Miter Gearbox

- JTP240 Miter Gearbox

- JTP280 Miter Gearbox

- Solid Input and Output Shafts Gearbox

- Solid Input and Hollow Output Gearbox

- Flange Input and Solid Output Gearbox

- Flange Input and Hollow Output Gearbox

- JTA Alu. Miter Gearbox

Lift System and Accessories

- Screw Jack System

- Lift System Accessories

-

- Flexible Jaw Coupling

- Overload Safety Couplings

- Aluminum Couplings

- Telescopic Universal Joint

- Rigid Shaft Couplings

- Universal Joint

- Cast Iron Hand Wheel

- Connecting Shafts

- Aluminum Handwheel

- YVF2 Series Variable Speed AC Motor

- Brake motors

- Three Phase Electric Motor

- Screw Jack Motor Flange

- Single Phase Induction Motors

- K Helical Bevel Geared Motor

- R Helical Geared Motor

- Worm Gear Reducer

- 12V 24V DC Geared Motor

- Proximity Switches

- Limit Switches

- Pillow Blocks

- Pillow Block Flange Bearing

- Digital Position Indicator

- Flange Blocks

- Ball Joint Rod End Bearing

- Bellows Boot

- Helical Gear Motor

- 12V 24V DC Motor

- Linear Bushings and Shafts

- Trunnion Adapters

- Servomotor

- Rotary Encoder

- Low Backlash Planetary Gearheads

- Stepper Motor

- 24V Planetary Gear Reducer

- Planetary Speed Reducer

- Frequency Inverter

- Hydraulic Cylinder Rod End Bearing

- Lift System Applications

Linear Actuators

- LAP Electric Linear Actuator

-

- 100KG Parallel Electromechanical Linear Actuators

- 250KG Parallel Electro Mechanical Linear Actuators

- 500KG Parallel Mount Rod Style Linear Actuators

- 630KG Parallel Mount Electric Cylinder Linear Actuators

- 1000KG Parallel Mount Industrial Linear Actuators Acme Screw

- 1600KG Parallel Electro-mechanical Actuators Heavy Duty

- 2500KG Parallel Mount Electric Cylinders Actuator

- 4000KG Heavy Duty Electric Linear Actuators Parallel Mount

- 6300KG Parallel Motor Drive Electric Actuator Linear Actuator

- 8000KG Parallel Electric Motor-Drive Linear Actuator

- 10000KG Parallel Mount Motorized Electric Linear Actuator

- 15000KG Parallel Industrial Motor Linear Actuator

- 20000KG Parallel Indistrial Motor Drive Linear Actuator

- 25000KG Parallel Electric Motor Linear Electric Actuator

- LA Electric Linear Actuators

-

- 10KG In-line Mini Electric Linear Actuators with Brake Motor

- 25KG In-line Electric Linear Actuator Push Rod

- 63KG In-line 700mm Stroke Electric Motor Linear Actuator

- 90KG In-line High Speed Motor Drive Electric Linear Actuator

- 100KG In-line Fast Speed Electric Linear Motor Linear Actuator

- 300KG Inline Industrial Electromechanical Linear Actuator

- 500KG In-Line Electric Linear Actuator

- 700KG Inline Heavy Electro Mechanical Actuators

- 1000KG In-line Heavy Duty AC Volt Industrial Linear Actuators

- JTE Classic Electric Cylinder

- Mechanical Linear Actuators

- JCA Cubic Electric Cylinder

Application

Jacton Industry Co.,Ltd.

Contact: Warren Lee

Contact: Warren Lee

Skype: jactonjack

Skype: jactonjack

T: 86-769-81585810

T: 86-769-81585810

F: 86-769-81585852

F: 86-769-81585852

E: sales@jactonindustry.com

E: sales@jactonindustry.com

W: www.screw-jack.com

W: www.screw-jack.com

Contact: Warren Lee

Contact: Warren Lee Skype: jactonjack

Skype: jactonjack T: 86-769-81585810

T: 86-769-81585810  F: 86-769-81585852

F: 86-769-81585852  E: sales@jactonindustry.com

E: sales@jactonindustry.com  W: www.screw-jack.com

W: www.screw-jack.com

VAT No. 9144190007026567X3, Copyright ©2013 www.screw-jack.com Jacton Industry Co.,Ltd. All Rights Reserved Site Map

Building 2, No. 1, DongCheng Road, Chang An, Dongguan, Guangdong, China. Phone: 86-769-81585810 | Fax: 86-769-81585852

China Screw Jack,Ball Screw Jack,Machine Screw Jack,Worm Gear Screw Jack,Bevel Gear Screw Jack,Miter Gearbox,Screw Jack Lift System Manufacturer

China Screw Jack,Ball Screw Jack,Machine Screw Jack,Worm Gear Screw Jack,Bevel Gear Screw Jack,Miter Gearbox,Screw Jack Lift System Manufacturer