Home» Lift System Accessories » Product Detail

Products

THE NAME:

Planetary Speed Reducer

Model: HF200-HF313

Categories: Lift System Accessories »

Place of Origin: Made In China

Brand Name: JACTON

Description:

When low rpm motorized screw jack or low lifting speed electric driven screw jack systems needs gear reduction mechanism with high quality, high precision, high power, high torque, made in Taiwan "SANYA" Brand Planetary Speed Reducer will be the best choices. Planetary Speed Reducer utilizes flanges to connect and assemble together, and is compatible with the Global IEC standard motor combination. It also can be applied with other speed adjustment equipment, which can be easily replaced, assembled and dismantled.

Characteristics Of A Planetary Speed Reducer

The transmission of planetary speed reducers differs from that of typical traditional gears. Traditional gears are only driven by the engaged surfaces between large and small gears and all the loadings are concentrated on the contact point, which tends to wear and crack the gears easily. In the case of high-speed ratio, more couples of engaged gears are required for multiple stages. This not only takes a large amount of space but also generates more abrading attrition. The clearance between the couple of engaged reducer gears in each stage also accumulates, and all the above reduce the efficiency greatly.

When the planetary speed reducer drives, the sun gear, planetary gears and internal gear ring are loaded on six contact points and are in mesh with internal gear trajectory to evenly distribute the impact load spread out over 360 degrees. This can reduce the abrasion between gears and prevent the gears from cracking. Planetary gears rotate in a floating way so their clearance is almost insignificant. Each stage of speed reduction will only need the engagement of intermittent gears, so the volume is relatively minimized and the maximum efficiency can reach up to 97%.

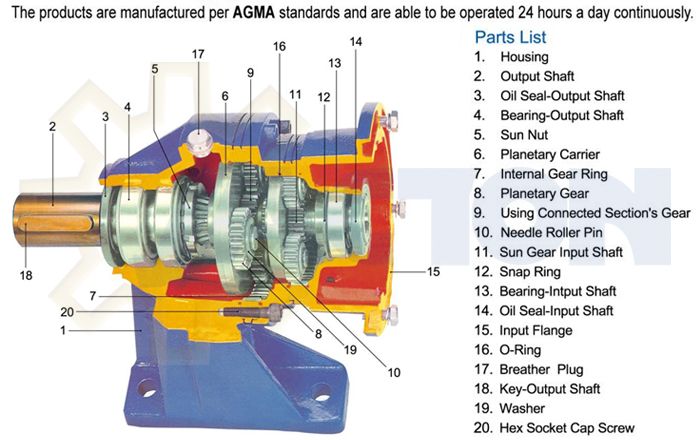

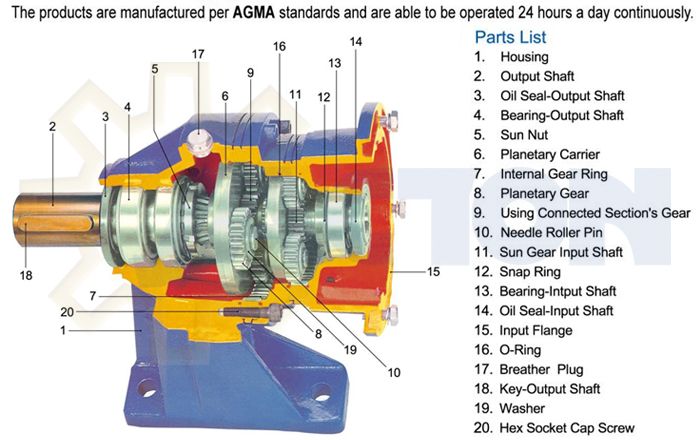

Characteristics Of A Planetary Speed Reducer Parts Structure

Planetary Speed Reducer Parts Structure includes housing, output shaft, oil seal-output shaft, bearing-output shaft, sun nut, planetary carrier, internal gear ring, planetary gear, using connected section's gear, needle roller pin, sun gear input shaft, snap ring, bearing-input shaft, oil seal-input shaft, input flange, o-ring, breather plug, key-output shaft, washer, hex socket cap screw etc.

An internal gear ring is firmly attached to the gearbox housing. There is an external power to drive the sun gear located in the center of the internal gear ring. Between two parts, there is a planetary gear set consisting of three gears that are equally assembled onto the carrier. This set of planetary gears are supported by an output shaft, internal gear ring and sun gear to float among them. When the power of the output end drives the sun gear, the sun gear can drive planetary gears to self rotate and follow the trajectory of the internal gear ring to perform the revolution around the center. The rotation of planetary gears will drive the output shaft connected with the carrier to transmit power.

Planetary Speed Reducer Motor Dimension

Planetary Speed Reducer Order Numbering Example

Planetary Speed Reducer HF Horizontal Flange Type Dimensions

Planetary Speed Reducer VF Vertical Flange Type Dimensions

Characteristics Of A Planetary Speed Reducer

The transmission of planetary speed reducers differs from that of typical traditional gears. Traditional gears are only driven by the engaged surfaces between large and small gears and all the loadings are concentrated on the contact point, which tends to wear and crack the gears easily. In the case of high-speed ratio, more couples of engaged gears are required for multiple stages. This not only takes a large amount of space but also generates more abrading attrition. The clearance between the couple of engaged reducer gears in each stage also accumulates, and all the above reduce the efficiency greatly.

When the planetary speed reducer drives, the sun gear, planetary gears and internal gear ring are loaded on six contact points and are in mesh with internal gear trajectory to evenly distribute the impact load spread out over 360 degrees. This can reduce the abrasion between gears and prevent the gears from cracking. Planetary gears rotate in a floating way so their clearance is almost insignificant. Each stage of speed reduction will only need the engagement of intermittent gears, so the volume is relatively minimized and the maximum efficiency can reach up to 97%.

Characteristics Of A Planetary Speed Reducer Parts Structure

Planetary Speed Reducer Parts Structure includes housing, output shaft, oil seal-output shaft, bearing-output shaft, sun nut, planetary carrier, internal gear ring, planetary gear, using connected section's gear, needle roller pin, sun gear input shaft, snap ring, bearing-input shaft, oil seal-input shaft, input flange, o-ring, breather plug, key-output shaft, washer, hex socket cap screw etc.

An internal gear ring is firmly attached to the gearbox housing. There is an external power to drive the sun gear located in the center of the internal gear ring. Between two parts, there is a planetary gear set consisting of three gears that are equally assembled onto the carrier. This set of planetary gears are supported by an output shaft, internal gear ring and sun gear to float among them. When the power of the output end drives the sun gear, the sun gear can drive planetary gears to self rotate and follow the trajectory of the internal gear ring to perform the revolution around the center. The rotation of planetary gears will drive the output shaft connected with the carrier to transmit power.

Planetary Speed Reducer Motor Dimension

Planetary Speed Reducer Order Numbering Example

Planetary Speed Reducer HF Horizontal Flange Type Dimensions

Planetary Speed Reducer VF Vertical Flange Type Dimensions

Previous Product:Hydraulic Cylinder Rod End Bearing

Next Product:12V 24V DC Motor

Product List

Manual Electric Screw Jack

Worm Screw Jack

- JTC Cubic Screw Jack

- JTM Worm Screw Jack

- JSS Stainless Steel Jack

- JT Acme Screw Jack

- JTW Machine Screw Jack

- Through Holes Screw Jack

- Custom Made Screw Jack

Ball Screw Jack

Bevel Gear Jack

Miter Gearbox

- JT Classic Miter Gearbox

-

- Order Code for Classic Miter Gearbox

- Classic Miter Gearbox description

- JT15 Miter Gearbox

- JT19 Miter Gearbox

- JT25 Miter Gearbox

- JT32 Miter Gearbox

- JT40 Miter Gearbox

- JT45 Miter Gearbox

- JT50 Miter Gearbox

- JT60 Miter Gearbox

- JT72 Miter Gearbox

- JT85 Miter Gearbox

- Flange Input Solid Output Shaft Gearbox

- JTP Cubic Miter Gearbox

-

- Order Code for Cubic Miter Gearbox

- Cubic Miter Gearbox description

- JTP65 Small Miter Gearbox

- JTP90 Miter Gearbox

- JTP110 Miter Gearbox

- JTP140 Miter Gearbox

- JTP170 Miter Gearbox

- JTP210 Miter Gearbox

- JTP240 Miter Gearbox

- JTP280 Miter Gearbox

- Solid Input and Output Shafts Gearbox

- Solid Input and Hollow Output Gearbox

- Flange Input and Solid Output Gearbox

- Flange Input and Hollow Output Gearbox

- JTA Alu. Miter Gearbox

Lift System and Accessories

- Screw Jack System

- Lift System Accessories

-

- Flexible Jaw Coupling

- Overload Safety Couplings

- Aluminum Couplings

- Telescopic Universal Joint

- Rigid Shaft Couplings

- Universal Joint

- Cast Iron Hand Wheel

- Connecting Shafts

- Aluminum Handwheel

- YVF2 Series Variable Speed AC Motor

- Brake motors

- Three Phase Electric Motor

- Screw Jack Motor Flange

- Single Phase Induction Motors

- K Helical Bevel Geared Motor

- R Helical Geared Motor

- Worm Gear Reducer

- 12V 24V DC Geared Motor

- Proximity Switches

- Limit Switches

- Pillow Blocks

- Pillow Block Flange Bearing

- Digital Position Indicator

- Flange Blocks

- Ball Joint Rod End Bearing

- Bellows Boot

- Helical Gear Motor

- 12V 24V DC Motor

- Linear Bushings and Shafts

- Trunnion Adapters

- Servomotor

- Rotary Encoder

- Low Backlash Planetary Gearheads

- Stepper Motor

- 24V Planetary Gear Reducer

- Planetary Speed Reducer

- Frequency Inverter

- Hydraulic Cylinder Rod End Bearing

- Lift System Applications

Linear Actuators

- LAP Electric Linear Actuator

-

- 100KG Parallel Electromechanical Linear Actuators

- 250KG Parallel Electro Mechanical Linear Actuators

- 500KG Parallel Mount Rod Style Linear Actuators

- 630KG Parallel Mount Electric Cylinder Linear Actuators

- 1000KG Parallel Mount Industrial Linear Actuators Acme Screw

- 1600KG Parallel Electro-mechanical Actuators Heavy Duty

- 2500KG Parallel Mount Electric Cylinders Actuator

- 4000KG Heavy Duty Electric Linear Actuators Parallel Mount

- 6300KG Parallel Motor Drive Electric Actuator Linear Actuator

- 8000KG Parallel Electric Motor-Drive Linear Actuator

- 10000KG Parallel Mount Motorized Electric Linear Actuator

- 15000KG Parallel Industrial Motor Linear Actuator

- 20000KG Parallel Indistrial Motor Drive Linear Actuator

- 25000KG Parallel Electric Motor Linear Electric Actuator

- LA Electric Linear Actuators

-

- 10KG In-line Mini Electric Linear Actuators with Brake Motor

- 25KG In-line Electric Linear Actuator Push Rod

- 63KG In-line 700mm Stroke Electric Motor Linear Actuator

- 90KG In-line High Speed Motor Drive Electric Linear Actuator

- 100KG In-line Fast Speed Electric Linear Motor Linear Actuator

- 300KG Inline Industrial Electromechanical Linear Actuator

- 500KG In-Line Electric Linear Actuator

- 700KG Inline Heavy Electro Mechanical Actuators

- 1000KG In-line Heavy Duty AC Volt Industrial Linear Actuators

- JTE Classic Electric Cylinder

- Mechanical Linear Actuators

- JCA Cubic Electric Cylinder

Application

Jacton Industry Co.,Ltd.

Contact: Warren Lee

Contact: Warren Lee

Skype: jactonjack

Skype: jactonjack

T: 86-769-81585810

T: 86-769-81585810

F: 86-769-81585852

F: 86-769-81585852

E: sales@jactonindustry.com

E: sales@jactonindustry.com

W: www.screw-jack.com

W: www.screw-jack.com

Contact: Warren Lee

Contact: Warren Lee Skype: jactonjack

Skype: jactonjack T: 86-769-81585810

T: 86-769-81585810  F: 86-769-81585852

F: 86-769-81585852  E: sales@jactonindustry.com

E: sales@jactonindustry.com  W: www.screw-jack.com

W: www.screw-jack.com

VAT No. 9144190007026567X3, Copyright ©2013 www.screw-jack.com Jacton Industry Co.,Ltd. All Rights Reserved Site Map

Building 2, No. 1, DongCheng Road, Chang An, Dongguan, Guangdong, China. Phone: 86-769-81585810 | Fax: 86-769-81585852

China Screw Jack,Ball Screw Jack,Machine Screw Jack,Worm Gear Screw Jack,Bevel Gear Screw Jack,Miter Gearbox,Screw Jack Lift System Manufacturer

China Screw Jack,Ball Screw Jack,Machine Screw Jack,Worm Gear Screw Jack,Bevel Gear Screw Jack,Miter Gearbox,Screw Jack Lift System Manufacturer