Home» Custom Made Screw Jack » Product Detail

Products

THE NAME:

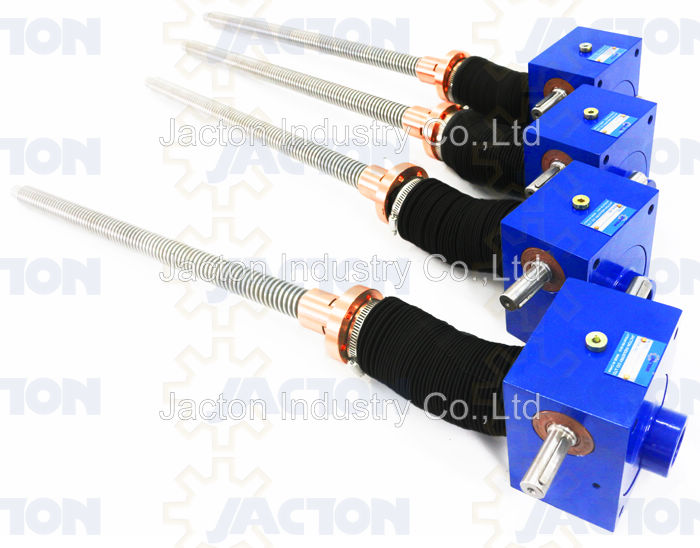

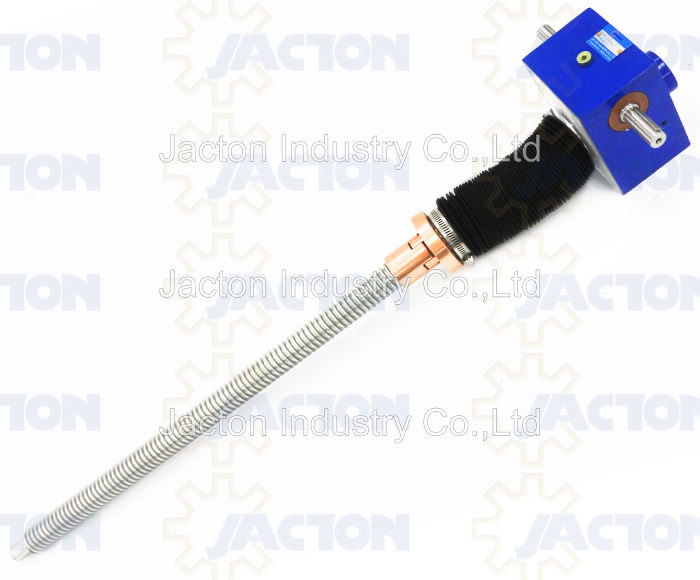

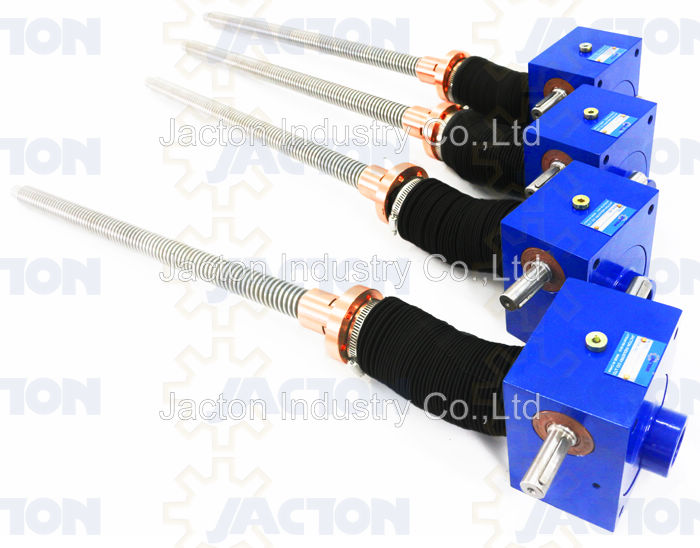

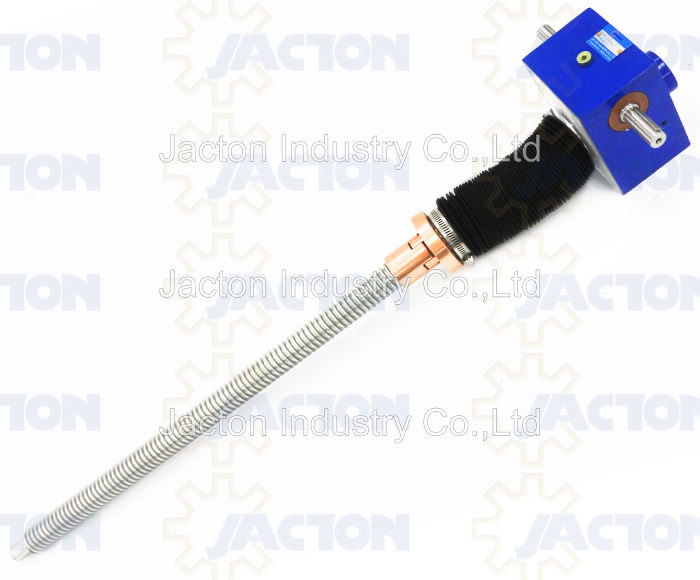

Safety Nut on a Rotating Screw Jack

Model: JTC25

Categories: Custom Made Screw Jack »

Place of Origin: Made In China

Brand Name: JACTON

Description:

A safety nut on a screw jack is an auxiliary nut, which follows the "lifting nut" on a rotating screw jack. In normal conditions the safety nut does not support any load. The failure of the threads of the worm gear will cause the load to be transferred to the safety nut preventing the load from falling. Requirement for personal safety measures and or conformity to accident-prevention standards (persons under raised load or working platforms). In the case of worm gear screw jacks used on theatre stages (lifting platforms or jacking systems that might affect personal safety, lifting elements are designed according to current regulations, and include such items as anti-drop systems (self-locking spindles and/or mechanical safety brakes as part of the drive system). The function of the synchronizing device is guaranteed, when required, by additional components.

Australia customers:

JTC25 inverted cubic screw jacks with supporting nut with short safety nut for visual wear monitoring.

If you have new machines or potential projects and would like to learn more information and price about high quality Safety Nut Screw Jacks, contact us today with your requirements. Our teams are looking forward to working with you. Important Note: most of our standard products with stock components, in other words, in stock and fast delivery.

Australia customers:

JTC25 inverted cubic screw jacks with supporting nut with short safety nut for visual wear monitoring.

If you have new machines or potential projects and would like to learn more information and price about high quality Safety Nut Screw Jacks, contact us today with your requirements. Our teams are looking forward to working with you. Important Note: most of our standard products with stock components, in other words, in stock and fast delivery.

Previous Product:America customer 5 tons machine screw mechanical actuator

Next Product:Double Clevis Screw Jack

Product List

Manual Electric Screw Jack

Worm Screw Jack

- JTC Cubic Screw Jack

- JTM Worm Screw Jack

- JSS Stainless Steel Jack

- JT Acme Screw Jack

- JTW Machine Screw Jack

- Through Holes Screw Jack

- Custom Made Screw Jack

Ball Screw Jack

Bevel Gear Jack

Miter Gearbox

- JT Classic Miter Gearbox

-

- Order Code for Classic Miter Gearbox

- Classic Miter Gearbox description

- JT15 Miter Gearbox

- JT19 Miter Gearbox

- JT25 Miter Gearbox

- JT32 Miter Gearbox

- JT40 Miter Gearbox

- JT45 Miter Gearbox

- JT50 Miter Gearbox

- JT60 Miter Gearbox

- JT72 Miter Gearbox

- JT85 Miter Gearbox

- Flange Input Solid Output Shaft Gearbox

- JTP Cubic Miter Gearbox

-

- Order Code for Cubic Miter Gearbox

- Cubic Miter Gearbox description

- JTP65 Small Miter Gearbox

- JTP90 Miter Gearbox

- JTP110 Miter Gearbox

- JTP140 Miter Gearbox

- JTP170 Miter Gearbox

- JTP210 Miter Gearbox

- JTP240 Miter Gearbox

- JTP280 Miter Gearbox

- Solid Input and Output Shafts Gearbox

- Solid Input and Hollow Output Gearbox

- Flange Input and Solid Output Gearbox

- Flange Input and Hollow Output Gearbox

- JTA Alu. Miter Gearbox

Lift System and Accessories

- Screw Jack System

- Lift System Accessories

-

- Flexible Jaw Coupling

- Overload Safety Couplings

- Aluminum Couplings

- Telescopic Universal Joint

- Rigid Shaft Couplings

- Universal Joint

- Cast Iron Hand Wheel

- Connecting Shafts

- Aluminum Handwheel

- YVF2 Series Variable Speed AC Motor

- Brake motors

- Three Phase Electric Motor

- Screw Jack Motor Flange

- Single Phase Induction Motors

- K Helical Bevel Geared Motor

- R Helical Geared Motor

- Worm Gear Reducer

- 12V 24V DC Geared Motor

- Proximity Switches

- Limit Switches

- Pillow Blocks

- Pillow Block Flange Bearing

- Digital Position Indicator

- Flange Blocks

- Ball Joint Rod End Bearing

- Bellows Boot

- Helical Gear Motor

- 12V 24V DC Motor

- Linear Bushings and Shafts

- Trunnion Adapters

- Servomotor

- Rotary Encoder

- Low Backlash Planetary Gearheads

- Stepper Motor

- 24V Planetary Gear Reducer

- Planetary Speed Reducer

- Frequency Inverter

- Hydraulic Cylinder Rod End Bearing

- Lift System Applications

Linear Actuators

- LAP Electric Linear Actuator

-

- 100KG Parallel Electromechanical Linear Actuators

- 250KG Parallel Electro Mechanical Linear Actuators

- 500KG Parallel Mount Rod Style Linear Actuators

- 630KG Parallel Mount Electric Cylinder Linear Actuators

- 1000KG Parallel Mount Industrial Linear Actuators Acme Screw

- 1600KG Parallel Electro-mechanical Actuators Heavy Duty

- 2500KG Parallel Mount Electric Cylinders Actuator

- 4000KG Heavy Duty Electric Linear Actuators Parallel Mount

- 6300KG Parallel Motor Drive Electric Actuator Linear Actuator

- 8000KG Parallel Electric Motor-Drive Linear Actuator

- 10000KG Parallel Mount Motorized Electric Linear Actuator

- 15000KG Parallel Industrial Motor Linear Actuator

- 20000KG Parallel Indistrial Motor Drive Linear Actuator

- 25000KG Parallel Electric Motor Linear Electric Actuator

- LA Electric Linear Actuators

-

- 10KG In-line Mini Electric Linear Actuators with Brake Motor

- 25KG In-line Electric Linear Actuator Push Rod

- 63KG In-line 700mm Stroke Electric Motor Linear Actuator

- 90KG In-line High Speed Motor Drive Electric Linear Actuator

- 100KG In-line Fast Speed Electric Linear Motor Linear Actuator

- 300KG Inline Industrial Electromechanical Linear Actuator

- 500KG In-Line Electric Linear Actuator

- 700KG Inline Heavy Electro Mechanical Actuators

- 1000KG In-line Heavy Duty AC Volt Industrial Linear Actuators

- JTE Classic Electric Cylinder

- Mechanical Linear Actuators

- JCA Cubic Electric Cylinder

Application

Jacton Industry Co.,Ltd.

Contact: Warren Lee

Contact: Warren Lee

Skype: jactonjack

Skype: jactonjack

T: 86-769-81585810

T: 86-769-81585810

F: 86-769-81585852

F: 86-769-81585852

E: sales@jactonindustry.com

E: sales@jactonindustry.com

W: www.screw-jack.com

W: www.screw-jack.com

Contact: Warren Lee

Contact: Warren Lee Skype: jactonjack

Skype: jactonjack T: 86-769-81585810

T: 86-769-81585810  F: 86-769-81585852

F: 86-769-81585852  E: sales@jactonindustry.com

E: sales@jactonindustry.com  W: www.screw-jack.com

W: www.screw-jack.com

VAT No. 9144190007026567X3, Copyright ©2013 www.screw-jack.com Jacton Industry Co.,Ltd. All Rights Reserved Site Map

Building 2, No. 1, DongCheng Road, Chang An, Dongguan, Guangdong, China. Phone: 86-769-81585810 | Fax: 86-769-81585852

China Screw Jack,Ball Screw Jack,Machine Screw Jack,Worm Gear Screw Jack,Bevel Gear Screw Jack,Miter Gearbox,Screw Jack Lift System Manufacturer

China Screw Jack,Ball Screw Jack,Machine Screw Jack,Worm Gear Screw Jack,Bevel Gear Screw Jack,Miter Gearbox,Screw Jack Lift System Manufacturer